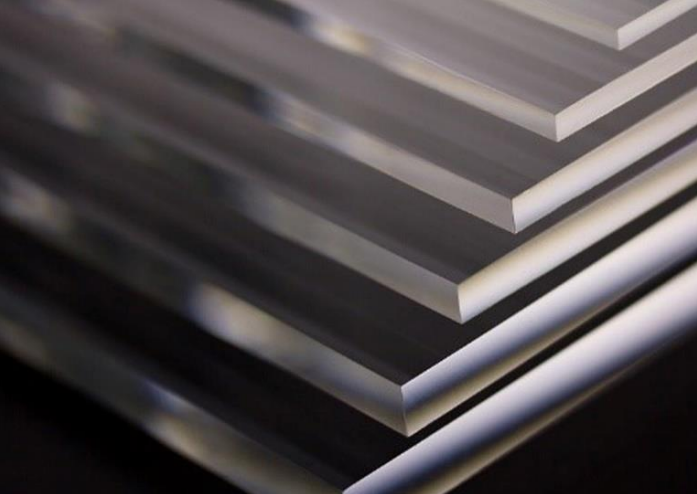

PMMA: Polymethyl methacrylate (Acrylic) or Plexiglas

Polymethyl methacrylate (PMMA), also known as acrylic or Plexiglas, is a transparent, rigid and lightweight thermoplastic material widely used for its excellent optical properties and ease of manufacture. Here is an overview of the main characteristics and applications of PMMA.

Main features

- Transparency: High optical transparency with light transmission of around 92%, similar to that of glass.

- UV and weather resistance: Excellent resistance to UV rays and weather conditions, does not yellow over time.

- Mechanical resistance: Good mechanical resistance, although less impact-resistant than polycarbonate.

- Lightweight: Approximately half the weight of the glass, making it easy to handle and install.

- Easy to make: Easy to cut, shape, drill and glue.

- Chemical resistance: Good resistance to many chemicals, but may be affected by some organic solvents.

- Thermal properties: Maximum operating temperature approx. 80°C to 90°C.

- Thermal and acoustic insulation: Good thermal and acoustic insulation.

Applications

PMMA is used in a variety of industries and applications because of its transparency, lightness and weather resistance.

- Signage and display industry: Signs, billboards and protective screens.

- Construction industry: Windows, skylights, roofs and safety glazing.

- Medical equipment: Lenses, medical devices and protective cases.

- Automotive and transport: Motorcycle windscreens, vehicle windows and lighting.

- Design and decoration: Furniture, aquariums, objets d’art and displays.

- Optics: Camera lenses, eyeglasses and optical instruments.

PMMA is valued for its unique combination of optical properties, durability and ease of manufacture, making it a versatile and reliable material for many industrial and commercial applications.

A project?

Our technicians will be happy to answer your questions.