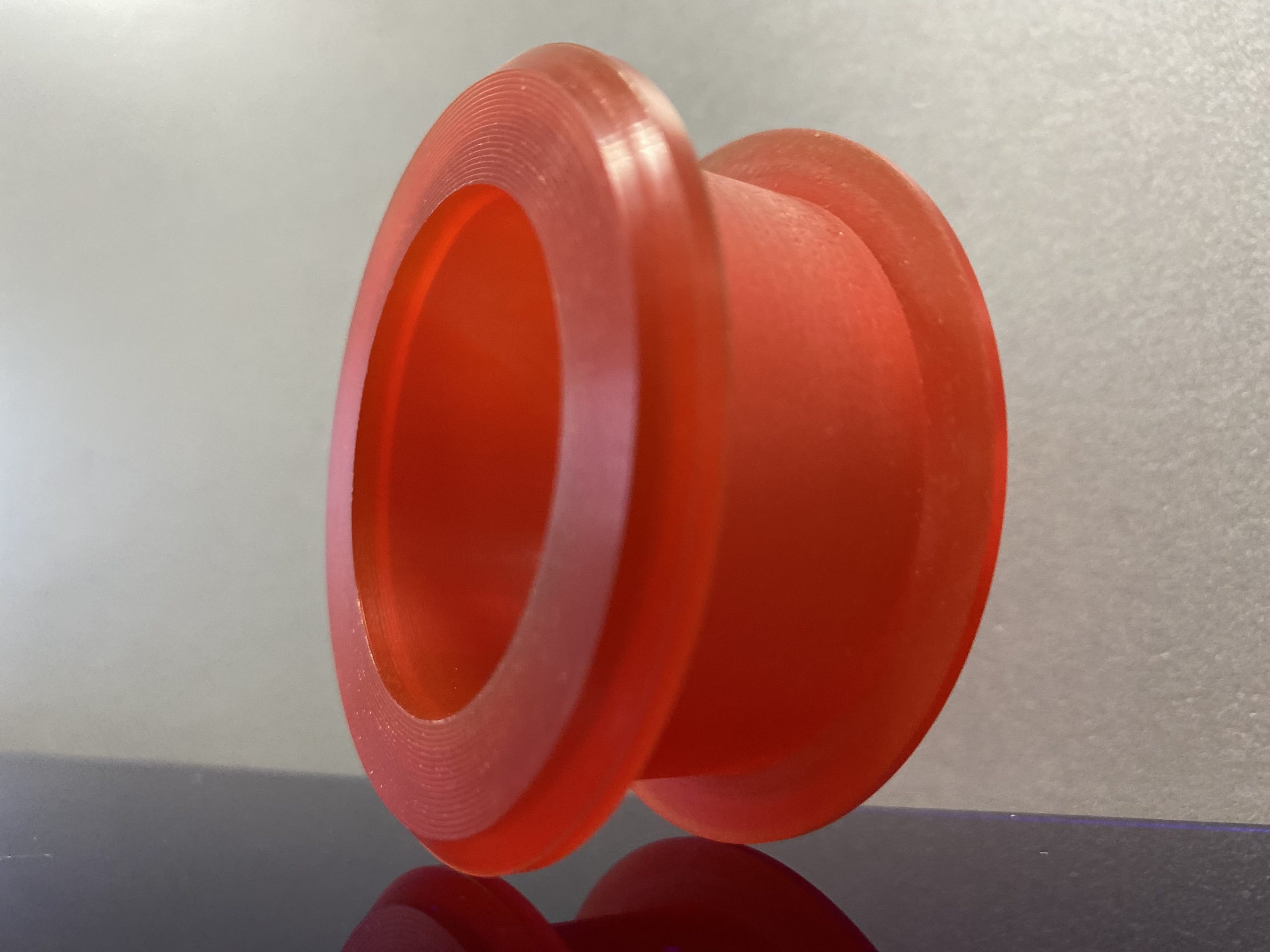

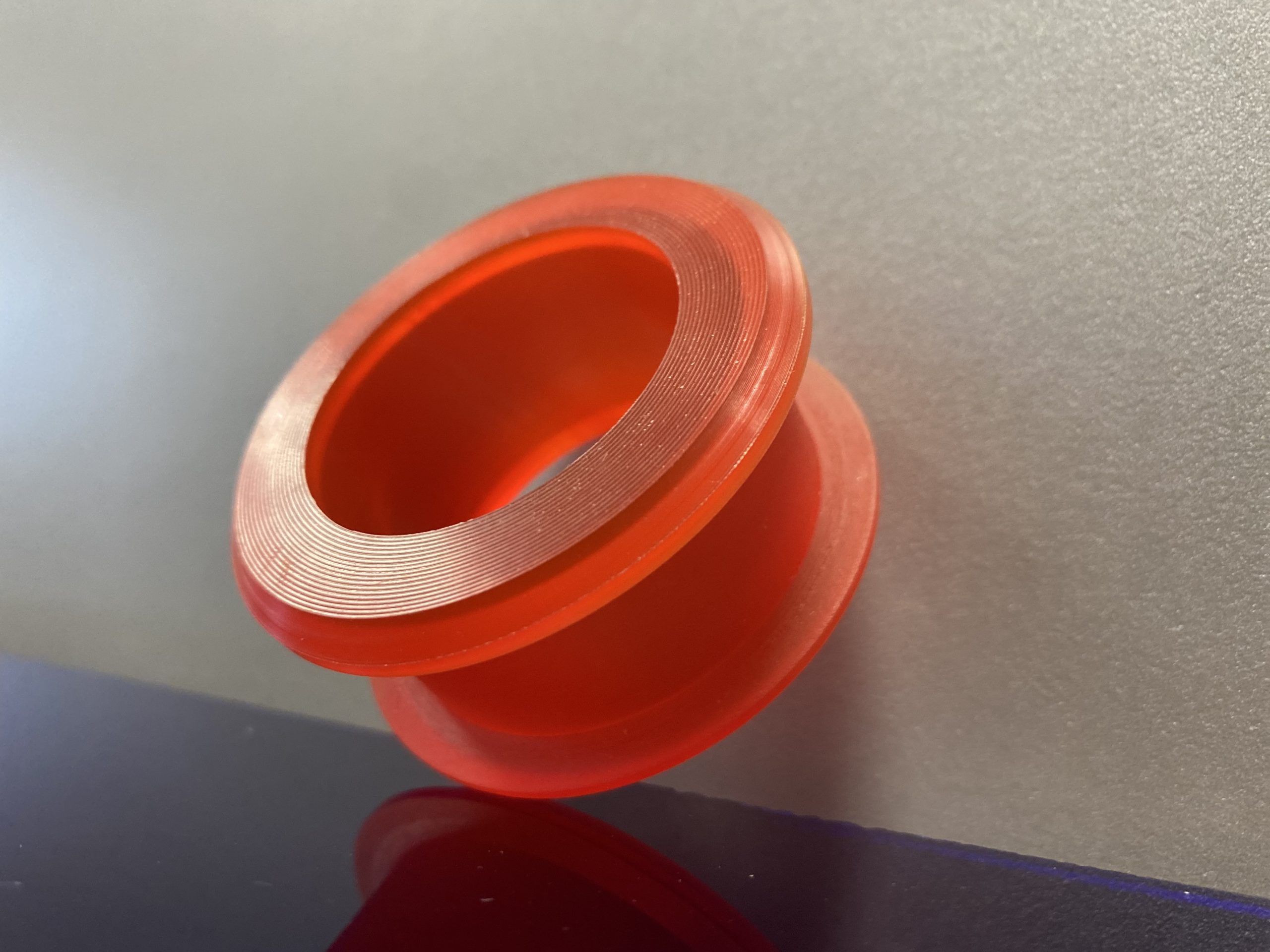

Polyurethane pulley 50shores

Polyurethane, renowned for its versatility, is a material of choice for the manufacture of many mechanical parts, particularly pulleys. With a hardness of 50 shores, this polymer offers an excellent compromise between rigidity and elasticity, making polyurethane pulleys particularly suitable for a wide range of applications.

Usefulness

By choosing a 50 shores polyurethane pulley, you’re opting for a durable, high-performance solution that’s suitable for a wide range of applications. This material offers excellent value for money and helps improve the efficiency of your equipment.

Benefits

- Wear resistance: 50 shores polyurethane offers excellent abrasion resistance, ensuring long pulley life even in tough working conditions.

- Resilience: This material has a high capacity to absorb shock and vibration, reducing noise and stress on other system components.

- Reduced coefficient of friction: Polyurethane pulleys offer a lower coefficient of friction than many other materials, improving energy efficiency and reducing belt wear.

- Chemical resistance: Polyurethane 50 shores is resistant to many chemicals, making it ideal for aggressive industrial environments.

- Adaptability: Polyurethane can be moulded in a wide variety of shapes and sizes, enabling customised pulleys to be made to meet specific requirements.

Applications

Polyurethane 50 shores pulleys have a wide range of applications in different sectors:

- Food industry: Thanks to their sanitary properties and resistance to chemicals, polyurethane pulleys are widely used in the food industry to transport products.

- Textile industry: They are used in textile machines to guide yarns and fabrics.

- Automotive industry: Polyurethane pulleys are used in transmission and suspension systems.

- Handling industry: They are used in conveyors and lifting systems.

A project?

Our technicians will be happy to answer your questions.