Previous

Next

Bienvenue

Artois Plastiques propose à ses clients un vaste assortiment de Semi-Produits issus des meilleures fabrications. Vous pouvez ainsi vous procurer des matières plastiques sous formes de barres, plaques, feuilles, panneaux et ébauches neuves.

En standard ou découpés à vos dimensions.

Nos domaines d'activité

Fabrication de pièces mécaniques simples à très complexes - Tous matériaux plastiques

Bureau d'études

et préconisation matière

Mécano-soudure

et chaudronnerie plastique

Matières

travaillées

Découpe et vente

de matières plastiques

Fabrication de pièces en élastomère

et polyuréthane

Nos moyens

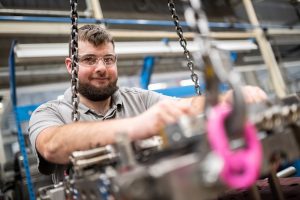

Outils de production

50 machines-outils conventionnelles et numériques, un atelier complet à la pointe de la technologie.

Bureau d'études

Un bureau d’études pour la réalisation de plans, d’études mécaniques, de préconisations matières premières.

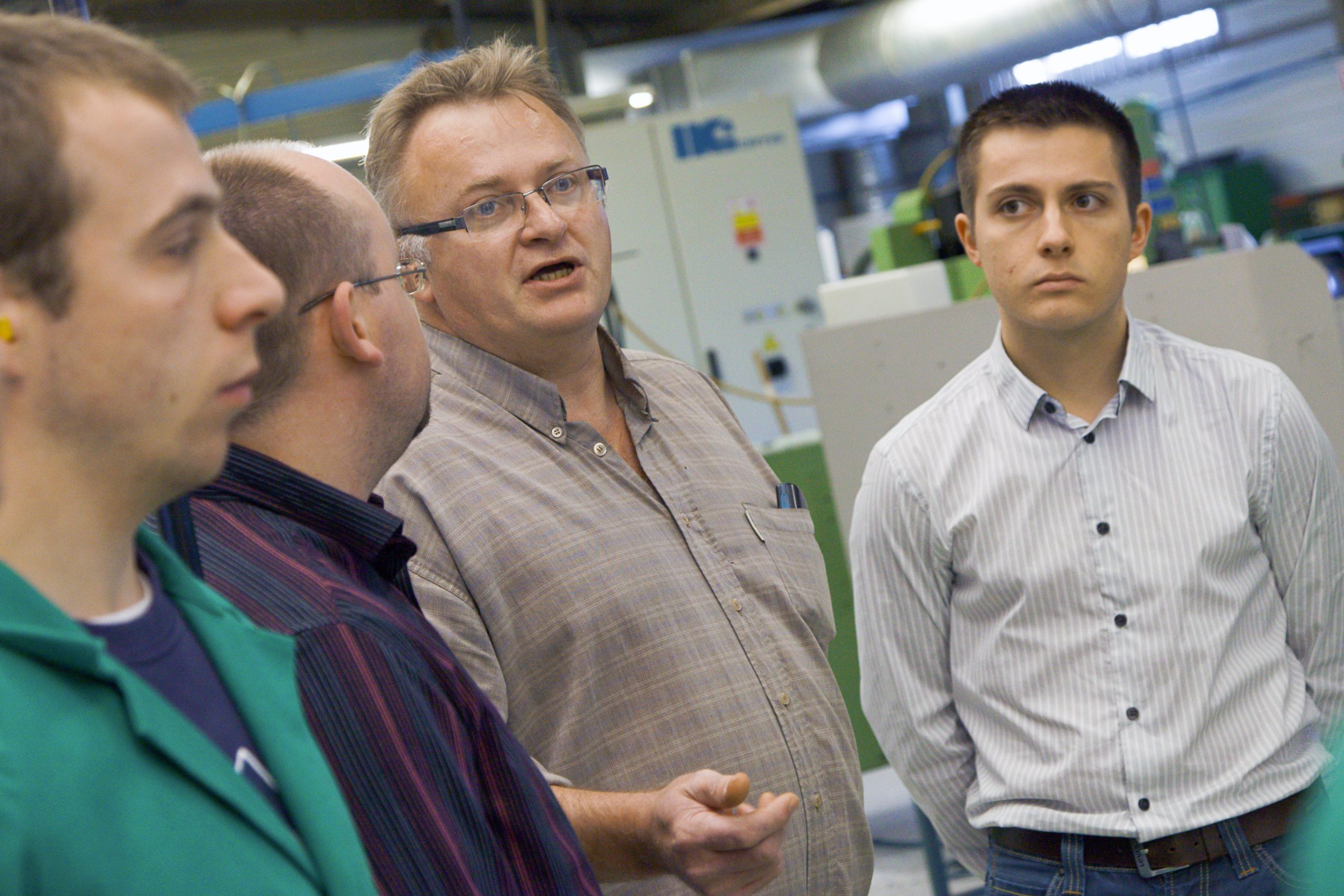

Moyens humains

20 techniciens de haut niveaux de qualification avec un état d’esprit basé sur le service et la qualité.